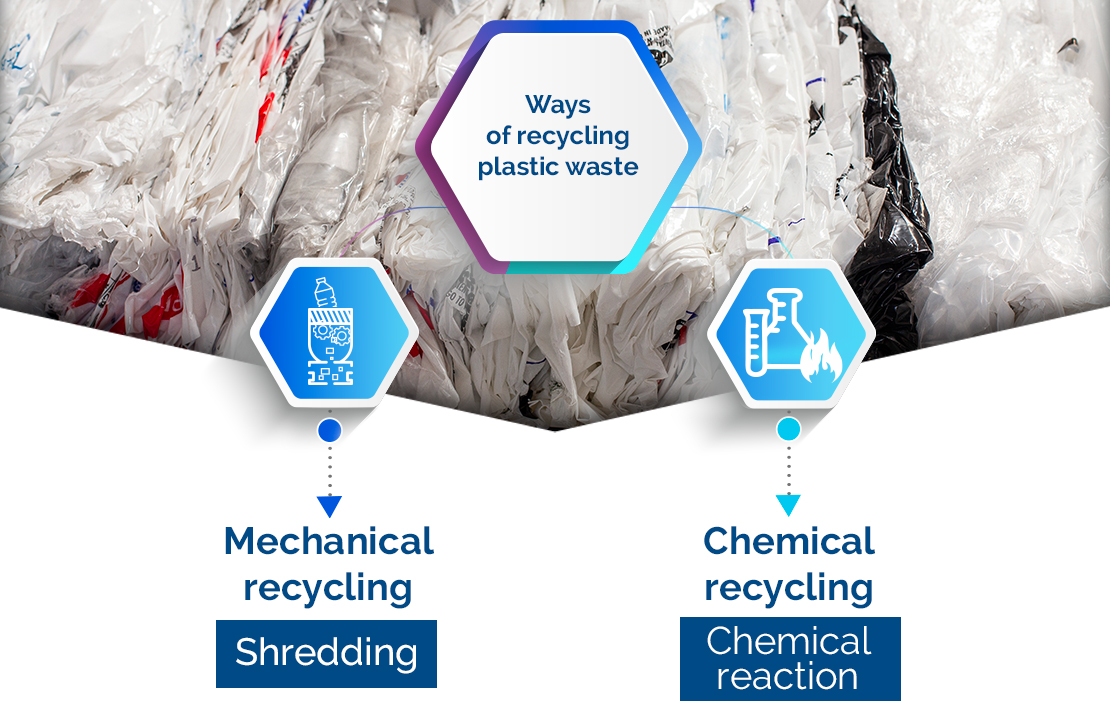

REGULATORY AFFAIRS

FOOD CONTACT FOR RECYCLED MATERIAL

Mechanical recycling

Mechanical recycling consists of sorting waste and shredding it in order to clean and decontaminate it before melting it down to make pellets.

Decontamination has its limits and small quantities of non-edible substances can be found in pellets. During the re-extrusion of these pellets, multiple substances can be formed (secondary reactions, degradation…) of which we do not have complete control and for some of which we do not know the nature and toxicological effects.

Mechanical recycling is well suited to pure materials (e.g. PET bottles). However, waste contains many products that combine several types of plastics (for optimum performance), plastics to which food residues adhere and plastics that cannot be sorted for recycling.

As far as polyethylene and polypropylene are concerned, mechanical recycling does not guarantee suitability for food contact.

Chemical recycling

Chemical recycling consists of breaking down plastic into monomers and oligomers (primary substances) which will make it possible to rebuild polymer chains.

The investment is negligible because the process is already in place in refineries and decontamination is total because the process only recovers the desired molecules (sorting by molecule).

Chemical recycling makes it possible to recycle materials that cannot be sorted in mechanical recycling and prevents them from ending up in incineration centers or landfill, which is currently a common practice.

Chemical recycling represents an economic opportunity because resulting products are similar in quality to those derived from fossil resources (oil, etc.). Therefore, they are suitable for food contact and can completely close the loop of circular economy!

LEYGATECH is able to provide you with both solutions!