MONO-MATERIAL SOLUTIONS

TO BECOME 100% RECYCLABLE

IN POLYETHYLENE (PE)

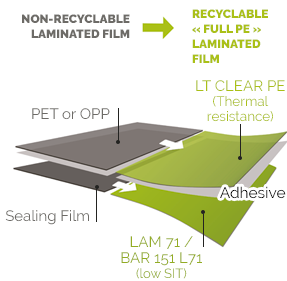

Replace your PET//PE and BOPP//PE laminate with :

Our OPE//P

or OPE//PE-EVOH-PE

solutions for lamination

- stiffness, transparency and thermal resistance.

- low SIT (Sealing Initiation Temperature) from 85°C.

Our solutions for direct use, without lamination

PE version

version with oxygen barrier

- high mechanical strength,

- thermal gap for optimised sealing,

- economic.

IN POLYPROPYLENE

(PP)

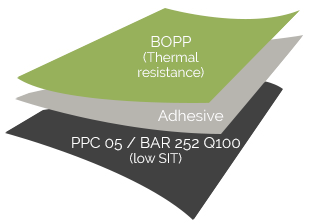

Our PP sealant films for lamination with OPP or BOPP

- sealing temperature of 110°C.

REDUCE

YOUR CARBON FOOTPRINT

BY USING BIO-BASED MATERIALS

Bio-based materials that can be carbon 14 dated

from sugarcane bagasse, allowing us to offer products containing 60% to 85% bio-based materials.

Bio-based materials used in a mass balance system

originating from green waste, this system requires ISCC Plus certification. Leygatech is the first French extruder to obtain this certification. We can offer products made from up to 100% bio-based materials.

BY USING CHEMICALLY RECYCLED MATERIALS

Chemical recycling is an extension of mechanical recycling. It allows, through different depolymerisation technologies, to return to the raw material which is ethylene. This ethylene is then steam-cracked to become polyethylene. Its use is also based on a mass balance system controlled by the ISCC.

We can offer products made from up to 100% chemically recycled materials.

- It’s suitable for food contact.

OUR PRODUCTS

Goal

Advantages

Goal

Advantages

– Recyclable into PE stream

– Thermal resistance

– Available with oxygen barrier option

Goal

Advantages

– Recyclable into PE stream

– Low SIT (Sealing Inititation Temperature)

Goal

Advantages

– Recyclable into PE stream

– Low SIT (Sealing Inititation Temperature)

– Oxygen barrier

Goal

Advantages

– Recyclable into PE stream

– Optimised sealing

– Competitive price

Goal

Advantages

– Recyclable into PE stream

– Optimised sealing

– Oxygen barrier

– Competitive price

Goal

Advantages

– Recyclable into PP stream

– Low SIT (Sealing Inititation Temperature)

Goal

PP sealing film with oxygen barrier, for lamination with BOPP or OPP

Advantages

– Recyclable into PP stream

– Low SIT (Sealing Inititation Temperature)

– Oxygen barrier